Purpose-Built

Process Solutions

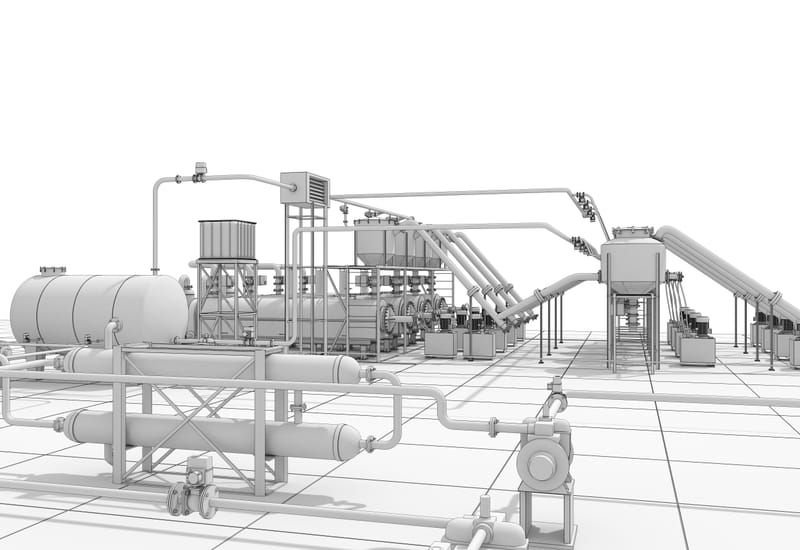

Concept to Engineered Excellence.

An Australian company leading the way in delivering innovative process solutions.

We don’t just supply equipment - we engineer performance.

mtt is more than a supplier - we’re your engineering partner

Our offering includes

Innovative Solutions

Innovative Solutions deliver forward-thinking engineering approaches that enhance performance, reduce costs, and solve complex operational challenges. Using advanced modelling, digital technologies, and creative design strategies, we develop customised solutions that optimise process efficiency, improve reliability, and enable smarter, more sustainable operations across oil & gas, petrochemical, water treatment, and industrial sectors.

Reliability and Durability

Reliability and Durability focus on designing systems and equipment that perform consistently under real operating conditions, with minimal failures and long service life. Through robust engineering, material selection, stress evaluation, and performance optimisation, we ensure assets remain safe, efficient, and dependable across oil & gas, petrochemical, water treatment, and industrial environments.

Expert Engineering Team

Our Expert Engineering Team combines deep technical knowledge with decades of hands-on industry experience to deliver high-quality, reliable, and innovative solutions. With specialists in process, mechanical, piping, structural, and flow assurance engineering, we provide precise analysis, practical design, and robust problem-solving for oil & gas, petrochemical, water treatment, and industrial projects.

Proven Track Record

With a Proven Track Record across global oil & gas, petrochemical, water treatment, and industrial projects, we deliver engineering solutions that perform reliably in the field. Our history of successful designs, optimisations, and project outcomes demonstrates our commitment to quality, technical excellence, and long-term client success.

Advanced cyclonic and inline separation technologies

Advanced cyclonic and inline separation technologies deliver high-efficiency removal of liquids, solids, and aerosols from gas and liquid streams. Using compact, high-performance cyclone designs and inline separators, we achieve superior separation efficiency, reduced footprint, low maintenance, and reliable operation for upstream, midstream, produced water, and process applications.

Falling film evaporators & Air-cooled heat exchangers (also known as fin fan)

Falling film evaporators and air-cooled heat exchangers (fin fans) provide efficient thermal transfer for demanding process applications. Falling film systems deliver gentle, high-efficiency evaporation for heat-sensitive fluids, while fin fans offer reliable cooling without water consumption. Together, these technologies support energy-efficient, low-maintenance operation in oil & gas, petrochemical, water treatment, and industrial facilities.

Complete modular process packages and skids

Complete modular process packages and skids deliver fully engineered, factory-built solutions for fast deployment and reliable operation. Designed for plug-and-play integration, these systems combine process equipment, instrumentation, controls, and structural framing into compact, transportable modules. Ideal for oil & gas, petrochemical, water treatment, and industrial projects requiring rapid installation, reduced site work, and high-quality engineering.

Compact flotation units (CFU) with patented performance

Compact Flotation Units (CFU) with patented performance deliver high-efficiency oil-water separation in a compact, low-maintenance design. Using advanced hydrodynamics and enhanced gas flotation, CFUs achieve exceptional removal of dispersed oil and fine solids while minimising footprint, energy use, and chemical consumption. Ideal for offshore, onshore, and produced-water treatment systems requiring proven, high-performance separation technology.

Design and supply of two & three phase separators and scrubbers

We specialise in the design and supply of high-performance two-phase and three-phase separators and scrubbers for gas–liquid and liquid–liquid separation. Using advanced modelling, droplet size analysis, and industry codes, we engineer reliable vessels with optimised internals including vane inlets, demisters, cyclones, and coalescers. Our solutions deliver stable operation, high separation efficiency, and industry-leading performance across oil & gas and industrial applications.

At MTT, we specialise in advanced fluid separation, delivering cutting-edge process engineering services and high-performance equipment to various industrial sectors. With a passion for innovation and a focus on results, we are trusted by our clients to solve complex separation challenges—from conventional methods to next-generation separation systems.

Our Expertise

We are a team of dedicated engineers, designers, and technical specialists who bring deep experience and advanced tools to every project. Whether you're building a new facility or upgrading an existing one, we provide tailored, data-driven solutions to improve system performance, reliability, and efficiency.

Powered by Insight

Using advanced process simulation, CFD, and performance modelling tools, we offer detailed assessments of your existing equipment—identifying opportunities to enhance throughput, reduce carryover, and extend asset life. Our engineering software suite supports precision design, optimisation, and troubleshooting, backed by real-world data and process know-how.

products & services

Separation Equipment for Demanding Industrial Applications

We are a leading provider of state-of-the-art separation equipment technology that delivers exceptional performance and reliability. Our extensive separation equipment range includes conventional mist eliminators, vane packs, cyclones, various inlet distributors, and plate pack coalescers. Some of our advanced technology includes next-generation axial flow cyclones developed to maximise separation efficiency and operating range. Our advanced separation equipment is crucial for efficient fluid separation in industries such as oil and gas, chemical processing, and mineral processing. We are fortunate to leverage the latest technologies and industry best practices to design and manufacture separation equipment that meet the highest standards of quality and performance. When you choose MTT, you can be confident that you are purchasing quality products that will meet or exceed your performance criteria.

Learn More

Produced Water Upgrades

Built around a patented coalescence process chamber, we offer solutions that are supplied in stand-alone compact flotation unit skids or used to upgrade and improve the efficiency and capacity of existing oil-water separation systems. Existing underperforming separation vessels or systems can be upgraded by retrofitting the Stauper coalescence chamber into the vessel or system. This upgrade will significantly improve oil from water separation, and degassing of the water while improving flow capacity. As a result of this upgrade our clients can expect improved separation performance a reduction in the need for costly chemicals and significantly improve the environmental footprint.

Tower Internals

We offer innovative solutions for mass transfer operations based on our extensive experience. We have developed cutting-edge separation equipment and systems that are at the forefront of mass transfer applications. Our advanced mass-transfer equipment and technologies are designed to deliver optimal performance. In addition, we provide a range of cost-effective services, including design, engineering, procurement, project management, and construction, to support various mass-transfer operations such as conventional and complex distillation azeotropic and extractive distillation liquid-liquid extraction absorber and stripper systems reactive distillation systems We are committed to meeting the unique needs of our clients by offering comprehensive solutions, from conceptual design to debottlenecking existing columns and complete process plant modernisation. Our expertise extends to the design and supply of various tower internals. Whether you require conventional trays, high-performance trays, random packing, structured packing, grid packing, or packed internals for distillation, absorption, stripping, and extractive distillation columns, we have you covered.

Learn More

Falling Film Evaporators

Falling film evaporators are employed in industries ranging from food and beverage production to pharmaceuticals and fine chemicals. They operate on a simple yet ingenious principle: a thin, continuous liquid film flows downward inside vertical tubes, while heat is applied to the exterior surfaces of these tubes. Controlled heat application causes the liquid to evaporate, forming vapour that rises upward, separating it from the concentrated liquid below. This efficient method maximises the surface area available for evaporation and minimises residence time and exposure to heat, thereby preserving the delicate characteristics of the product being processed. In the food and beverage sector, they play a crucial role in concentrating juices, reducing milk, and extracting flavours and essences with minimal thermal degradation. In pharmaceuticals, these evaporators are used for producing concentrated active ingredients and isolating pure compounds. Similarly, in chemical processing, they facilitate the separation and purification of various fine chemicals, contributing to the production of high-quality fine chemicals and intermediates.

Learn More

Engineering Design, Optimisation & Troubleshooting

We understand the importance of efficient and reliable engineering solutions and equipment. That is why our team of experienced engineers is dedicated to providing industry-leading services and equipment that cater to our client's unique separation requirements. From specialist separator and equipment design to process simulation, feasibility studies, front end engineering and design (FEED) to process optimisation and troubleshooting, we have the expertise and tools such as process simulation, computational fluid dynamics (CFD), finite element analysis (FEA) and structural analysis software to deliver effective solutions that improve performance, reduce downtime, and enhance overall efficiency. MTT is a reliable partner that books specialist outcomes not hours preventing project cost blowouts and minimising risk.

Learn MoreBy combining rigorous technical analysis with practical, field-proven design experience, we solve complex process challenges across the full project lifecycle. From early-stage concept development and FEED through to detailed engineering, fabrication support, and commissioning, our solutions are engineered for real operating conditions.We also specialise in optimising existing facilities through debottlenecking, performance assessment, and targeted upgrades that extend asset life and improve operational stability.

Our data-driven approach reduces operating costs, increases throughput, enhances separation and heat transfer efficiency, and minimises downtime. These capabilities are applied across traditional oil & gas, petrochemical, water treatment, as well as renewable energy and unique industrial applications, delivering measurable improvements in performance, safety, and long-term reliability.