Engineering Design,

Optimisation & Troubleshooting

We offer a wide array of engineering services tailored to meet the diverse needs of our customers. Our expertise spans multiple engineering disciplines, ensuring that we provide comprehensive solutions for every project.

Structural/Civil Engineering

Providing comprehensive analysis and design services to ensure the safety and durability of structural and civil design following industry code.

Project Management

We oversee the entire project from inception to completion, ensuring that it is delivered on time and within budget.

Drafting

Various 3D modelling software packages to create precise and detailed representations of engineering designs.

At MTT we are committed to delivering high-quality engineering solutions that drive success and innovation in every project.

services

Process Engineering Services

With decades of hands-on experience, we deliver accurate simulations, fast turnaround, and practical engineering that reduces CAPEX/OPEX while improving production uptime. Whether you require a full process design package, equipment selection, a performance audit, or optimisation of existing assets, our engineers provide robust, data-driven solutions that meet international standards.

Heat Exchanger Design

We provide specialised heat exchanger design services covering thermal sizing, mechanical design, and performance optimisation for shell-and-tube, plate, air-cooled, and custom heat transfer equipment. We ensure correct duty, approach temperature, pressure drop, fouling factors, and material selection to deliver efficient, reliable, and compliant designs. Our engineers develop full thermal calculations, TEMA-compliant layouts, mechanical datasheets, and fabrication-ready specifications to optimise heat transfer performance and reduce operating costs.

Dynamic Multiphase Flow Simulation

Dynamic Multiphase Flow Simulation provides time-dependent modelling of gas–liquid–solid behaviour in pipelines, separators, risers, and process equipment. It predicts slugging, pressure fluctuations, phase distribution, transient upsets, and operational risks. This advanced analysis supports safer design, improved reliability, and optimised performance across oil & gas, petrochemical, and produced-water systems.

Acoustic Design

Acoustic Design focuses on controlling noise and vibration in industrial facilities, ensuring compliance with environmental limits, protecting worker safety, and improving equipment reliability. Using advanced modelling and acoustic analysis, we assess noise sources, predict sound propagation, and develop mitigation solutions such as silencers, insulation, barriers, and layout optimisation for oil & gas, petrochemical, and industrial plants.

Computational Fluid Dynamics

Computational Fluid Dynamics (CFD) provides detailed insight into complex fluid behaviour, enabling accurate prediction of flow patterns, pressure drops, turbulence, heat transfer, and multiphase interactions. Using advanced simulation tools, we optimise equipment design, troubleshoot performance issues, and enhance efficiency across separators, vessels, pipelines, heat exchangers, and process systems in oil & gas and industrial applications.

Pressure Vessel Design

Pressure Vessel Design ensures safe, compliant, and efficient operation of vessels under internal or external pressure. Using ASME VIII, API, and international standards, we perform mechanical design, sizing, stress analysis, nozzle loading checks, material selection, and fabrication detailing. Our engineering supports high-integrity vessels for oil & gas, petrochemical, water treatment, and industrial applications.

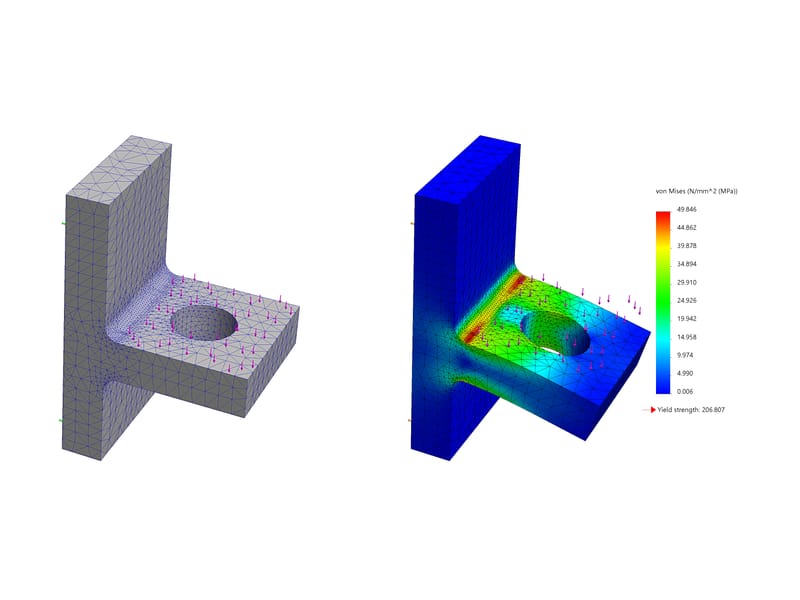

Finite Element Analysis

Finite Element Analysis (FEA) provides detailed structural insight into how components behave under stress, pressure, vibration, and thermal loads. Using advanced simulation tools, we evaluate deformation, fatigue, stress concentrations, and failure risks to optimise mechanical design, verify code compliance, and improve equipment reliability across pressure vessels, piping, supports, frames, and industrial structures.

Pipeline Design

Pipeline Design ensures safe, efficient, and reliable transport of fluids across oil & gas, petrochemical, water, and industrial systems. We provide full engineering services including sizing, route planning, stress analysis, hydraulic modelling, material selection, surge assessment, and code-compliant design to ASME, API, and international standards. Our designs optimise performance while reducing operational risk.

Piping Stress Analysis

Piping Stress Analysis evaluates how process piping behaves under thermal expansion, pressure loads, vibration, and external forces. Using advanced modelling and ASME B31 standards, we assess stresses, support requirements, nozzle loads, flexibility, and dynamic effects to ensure safe, compliant, and reliable piping systems across oil & gas, petrochemical, water, and industrial facilities.

Pipeline Installation Analysis

Pipeline Installation Analysis evaluates the forces, stresses, stability, and environmental conditions affecting onshore and offshore pipeline installation. Using advanced modelling, we assess load-out, towing, lifting, laydown, buckling, tension, and seabed interaction to ensure safe, efficient, and code-compliant installation. This analysis minimises construction risks and supports reliable pipeline deployment across oil & gas and industrial projects.